Refractory condition monitoring

Reveal 360

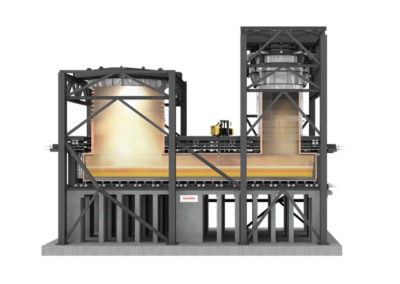

The Solution for monitoring inner surfaces in high temperature conditions

Reveal 360 is the complete solution for monitoring inner surfaces of ladles, converters and furnaces in high temperature conditions. Visual data of target surface condition is available online in unprecedented detail and presented utilizing an intuitive user interface.

Overview

Applications

- Refractory wear and sharp image of surface condition

- Flash Smelting Furnaces

- Ladles and EAFs

Features

- Accurate 2D imaging of inner surface

- Combined with laser scanned topography data

- Image data and topography storage to cloud service

- Value added features like automatic reaction index

- Integration to Level 2 and 3 systems

- Extremely easy-to-use web browser interface

Benefits

- Monitoring is fully objective and accessible to more than one individual

- Systematic inspection after each melt – trends and correlations made easily

- Optimized use and maintenance of refractory materials

- Systematic and full documentation for later tracking, process development or quality problem solving

- Work safety improved