Sapotech’s first Reveal CAST system in Japan was successfully commissioned at the beginning of January.

The first Reveal CAST surface inspection system has been successfully taken into use in Japan. The system was installed on a grinding machine that processes steel ingots of various shapes and sizes. The system ensures product quality and improves the throughput of the grinding process.

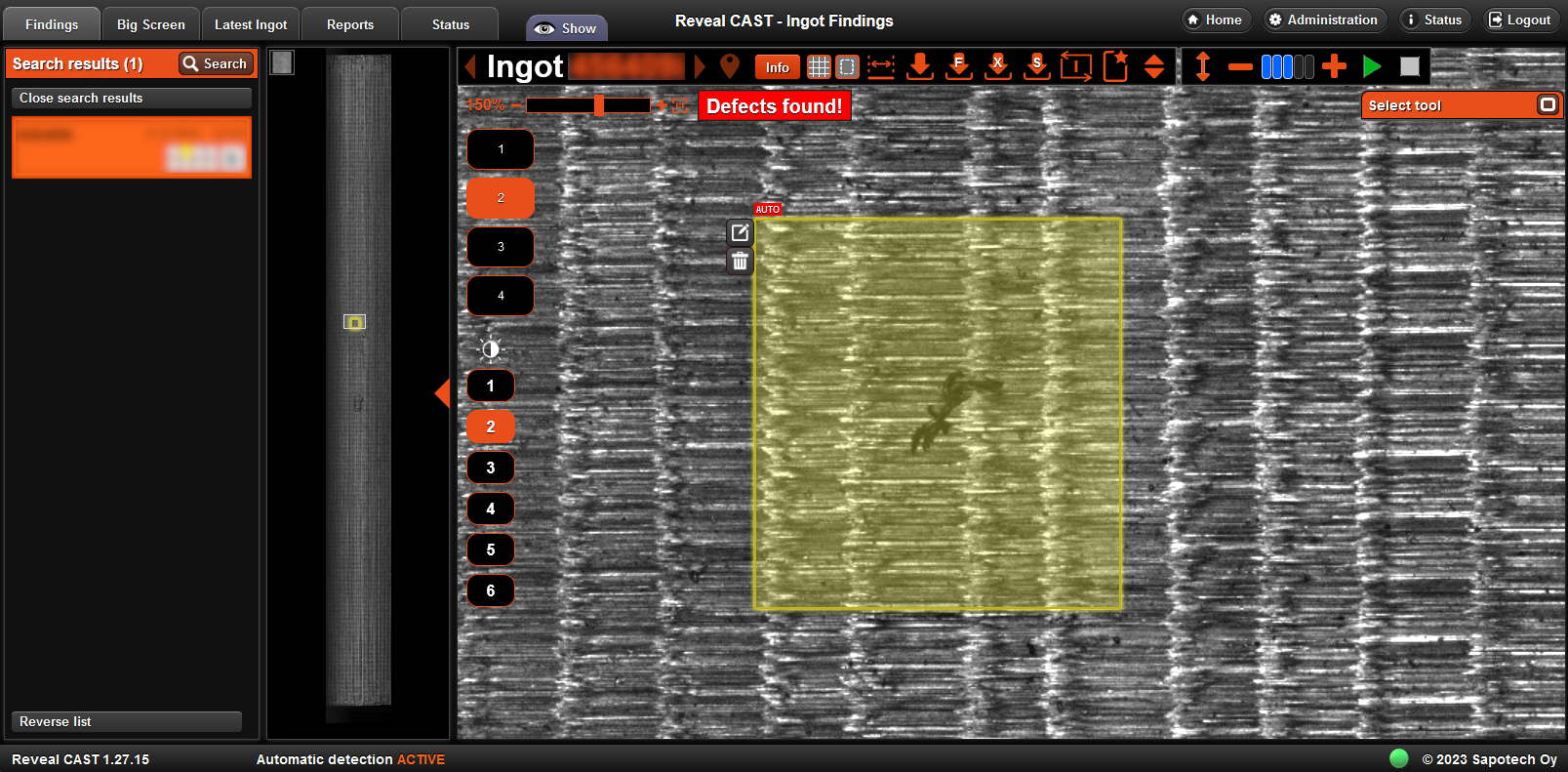

Surface inspection system has been designed to provide superior image quality from cast and ground ingot surfaces. Once the ingot of certain thickness arrives to the grinding machine, the automatic lifting device moves cameras and illumination units to a correct height to keep constant distance between the system and ingot top surface. The thickness variation that the system covers, is well over 1000 mm. The field of view of the system has been set to cover objects with a width of 1500 mm. Once the system is in correct height, the system is ready to image the ingot surface. Operator moves the grinding machine over the ingot with static speed, while the system takes high-resolution images from the surface. Reveal CAST then combines the individual area scan images together to form a full super-resolution surface image from the ingot.

The system is equipped with Sapotech’s Deep Neural Network (DNN) defect detection and classification engine, which is trained remotely by utilizing Sapotech’s secure remote connection. Typical ingot defects are detected and their position on ingot surface is pinpointed for operators’ immediate action. The detection results are provided within 15 seconds or faster to aid operator’s everyday work. It is expected that the throughput as well as quality will be enhanced as operator does not need to move away from the cabinet to inspect the ingot but can see the detected defects from his working position and continue the grinding when required.

Today, Sapotech’s Reveal CAST surface inspection system can be found from billet, slab and ingot grinding machines. It doesn’t matter if the grinding machine moves and the object is static or if the object moves under the system, the outcome is always a perfect image quality and detection results. In case you need a solution to inspect surfaces with ground surface finishing, please do not hesitate to contact us. If you are looking for a comprehensive solution for grinding of semi products in metals industry combined with Sapotech’s surface inspection, we are more than happy to help you with our partner The Evertz Group!