High free opening rate of ladles is a key factor during steelmaking to keep steel quality high and for safety purposes. To ensure high opening rate, steelmakers use filler sand to avoid a direct contact of the liquid metal with the slide gate-system of the steel ladle. However, the quality and amount of added filler sand are not enough. It is important to also have a correct positioning of the sand, so the slide gate is protected and there is a high ladle opening rate.

Our solution

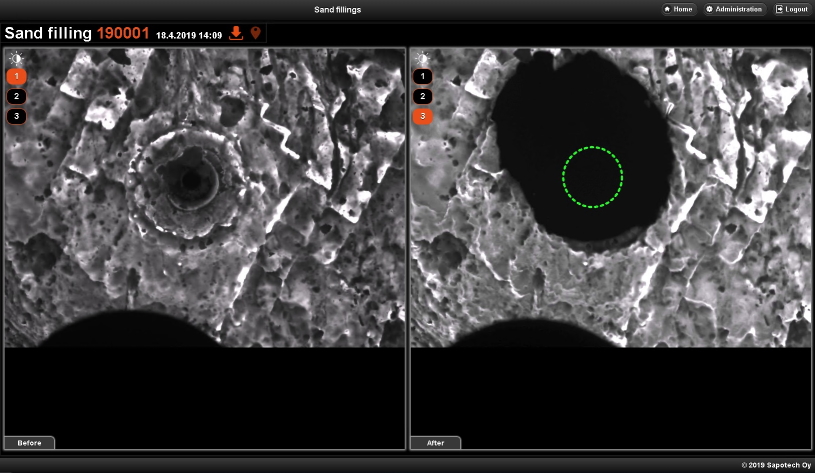

Our customer needed to monitor in real-time and with high-detail the condition of the slide gate area before and after the filler sand addition. Reveal TAP has been successfully delivered for this purpose. Also, Reveal TAP provides artificial intelligence (AI) tools that automatically assist the operators in ladle positioning and sand addition.

Benefits for the customer

One of the benefits of Sapotech products is their flexibility to adapt to customers specific needs. The delivered application is an excellent example of the versatility of Reveal TAP. It also shows how intelligent algorithms can be used to efficiently improve process monitoring and process efficiency.

In this case, Reveal TAP is used to increase the ladle free opening rate through more accurate filler sand addition because it is easier to position the ladle for sand addition with the help of our intelligent algorithms. Also, there is real-time feedback to the operator about the slide gate area condition as well as a systematic documentation that is gathered for process tracking and optimization. Finally, our customer can increase savings because of the decreased process breaks, damages to refractories and ladle shell besides increasing work safety.