In this article we will be discussing about the use of Reveal TAP system in freeboard measurement and how it is increasing safety and efficiency in metal production.

Description

In context of molten metal processes, “freeboard measurement” typically refers to the vertical distance between the surface of the molten metal or slag and the top of the metallurgical vessel, such as ladle or slag pot.

Determining the freeboard height is important in the metal industry as it helps operators to monitor and control the surface level of molten metal or slag in the vessel. Maintaining the appropriate freeboard height is important for several reasons such as safety, process control, and quality control, which will be further discussed in the “Benefits” section.

There are various methods for evaluating freeboard height. Sapotech has developed a specialized solution named Reveal TAP for freeboard measurement. This application, as its name suggests, is designed for the specific purpose of determining freeboard height by incorporating infrared cameras and an advanced freeboard detection algorithm for accurate measurements.

The next paragraph will explore the system in more detail.

Application

In the metal industry, determining the freeboard measurement is crucial for several reasons. Underfilling ladles is undesirable as it is highly inefficient, and overfilling is also avoided due to the potential hazards posed to workers and the risk of equipment damage. Additionally, in production, it is essential to know how much molten metal progresses to the next processing stage, aiming to optimize ladle filling.

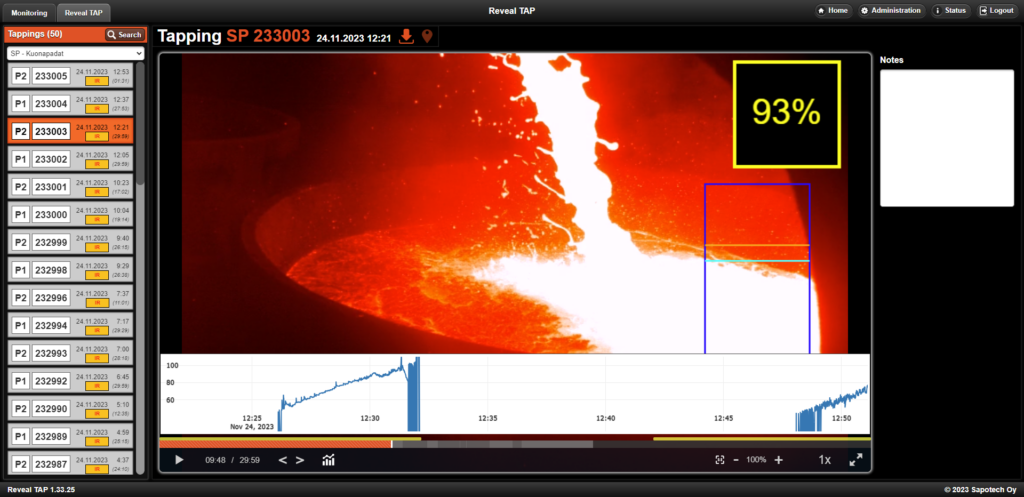

Conventional approaches to determine freeboard height, such as visual observation, prove challenging in factory conditions. Fumes and gases produced during the process block visibility, while extreme temperatures pose a risk to operators. Reveal TAP for freeboard measurement utilizes thermal cameras capable of seeing through heavy smoke and gases, allowing for accurate imaging each time. The system automatically detects the start of the tapping, while intelligent algorithms monitor the freeboard height. Operators can simultaneously observe the process through the system’s live feed. An alert is triggered by the system once the desired freeboard height is achieved. In figure 1, a reference picture of the Reveal TAP user interface is presented. The user interface enables the review of previous recordings and the monitoring of the freeboard measurement through the live feed.

Figure 1. Reference picture of the Reveal TAP user interface.

Sapotech, with its extensive experience in challenging process conditions, has designed this solution considering the demanding conditions of steel and other metal production plants. The camera or cameras are housed in a robust casing designed to withstand high temperatures, splashes of molten metal, and dust. In addition to the camera, the system includes a control cabinet and other possible accessories, such as traffic lights that indicate ladle filling levels to the operators working outside the control room. The system also includes a user-friendly interface, allowing operators to review the recordings afterwards.

Benefits

The Reveal TAP for Freeboard Measurement offers many benefits to its user, such as:

- Enhanced safety: Improved monitoring and control of freeboard height contribute to a safer working environment by minimizing the risk of accidents associated with overfilling ladles.

- Operational efficiency and process optimization: The Reveal TAP optimizes ladle filling, reducing inefficiencies related to both under- and overfilling. This leads to increased operational efficiency and productivity. In addition, optimizing ladle filling contributes to better control over downstream processing stages and overall steel/metal production efficiency.

- Equipment protection: Accurate freeboard measurement helps prevent equipment damage caused by overfilling the ladles, minimizing downtime and maintenance costs.

- Quality control: Maintaining precise freeboard height ensures the consistency and quality of the molten metal, positively impacting the final product’s quality.

- Remote monitoring: Users can observe the ladle filling process in real-time through live stream, allowing for remote monitoring and timely decision-making.

- User-friendly interface: The Reveal TAP system includes user-friendly interface for operators for efficient and easy management of the freeboard measurement process.

- Easy to install: The system facilitates straightforward installation in different locations, and it is easy to customize to meet the specific needs of customers, providing flexibility in adapting to various requirements.

In conclusion, Reveal TAP for freeboard measurement presents a solution for the challenges faced in the metal production industry. The system ensures precise freeboard measurement, improving safety, operational efficiency, and equipment protection. Its user-friendly interface and adaptability to extreme process conditions makes it a reliable choice for steel and metal production plants.

The system already has several satisfied customers. If you would like to learn more about this solution or our other solutions, please do not hesitate to contact us.

Also, don’t forget to follow us on LinkedIn!