The article series continues, and this time, the focus is on the utilization of the Reveal TAP system for metal/slag detection.

Detecting and separating metal from slag during tapping in metal production is important when considering product quality, cost and energy efficiency, and worker safety. This article will give an overview of the system and explain how it can positively impact on these matters.

Description

Molten metal and slag have different thermal properties due to their different chemical composition and temperature. Reveal TAP for metal/slag detection is based on detecting these differences in real time. The technology used relies on infrared cameras. The emissivity characteristics of slag and metal are very different, especially in high temperatures. With IR cameras it is possible to distinguish this difference in emissivity as perceived temperature changes between the two phases of the tapping stream. The cameras capture the thermal radiation emitted by these materials and convert it into a visual image where different colors indicate differing perceived temperatures.

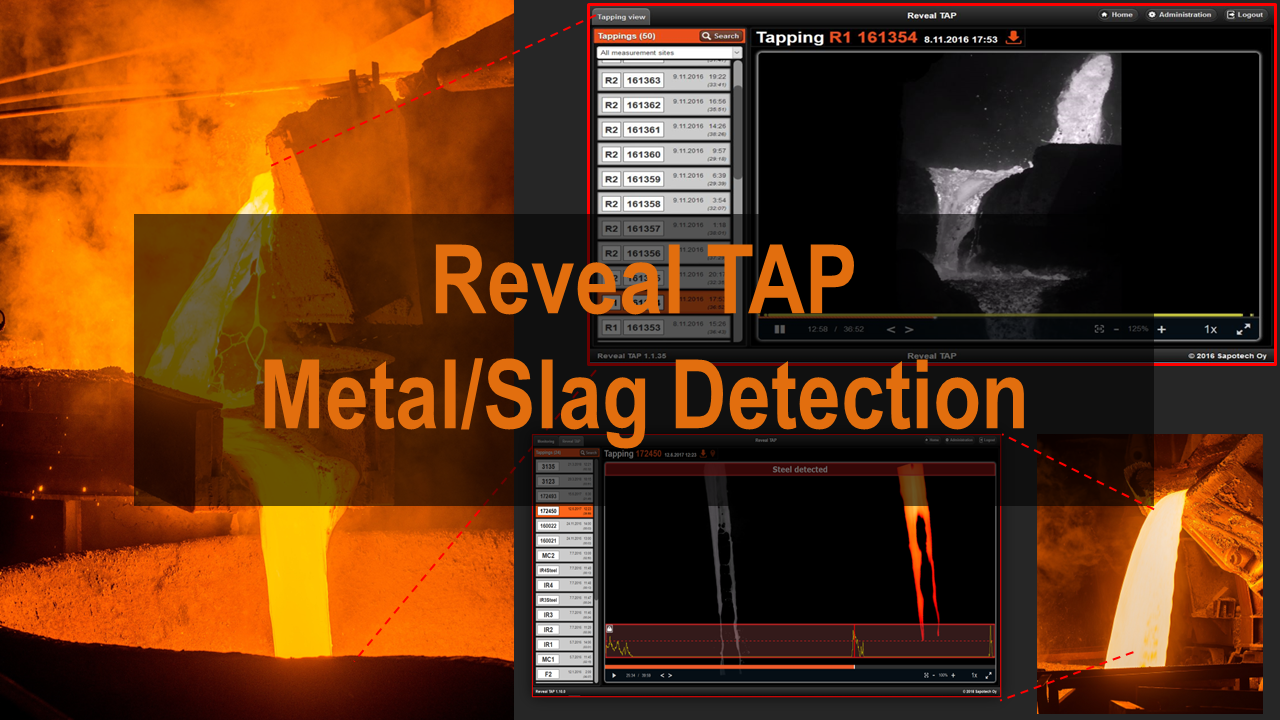

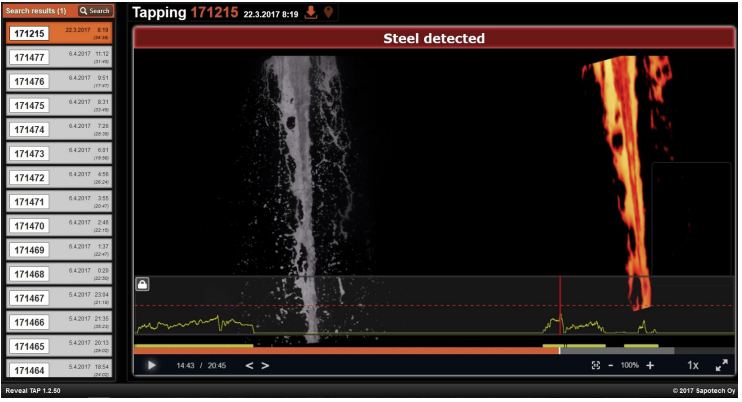

By interpreting these temperature differences, Reveal TAP can effectively distinguish metal and slag from each other. The system uses high-resolution infrared cameras and adaptable detection algorithms designed to identify the transition between metal and slag during the tapping process. The technology and hardware used are designed to withstand extreme process conditions. In addition, the cameras used can see through heavy smoke and fumes, ensuring a clear image at each stage of the process. Figure 1 shows a reference image of how tapping looks like in the Reveal TAP user interface.

Figure 1. Reveal TAP user interface for metal/slag detection.

The system automatically recognizes the start of the tapping process and starts to record it. Operators see a real-time view of the tapping process, and this live feed is also saved for later use. Also, as seen in Figure 1, when a predefined metal/slag threshold is reached, an alarm is triggered giving the user real-time feedback and information of the ongoing process. This enables the users to better control the process and optimize the operation.

Application

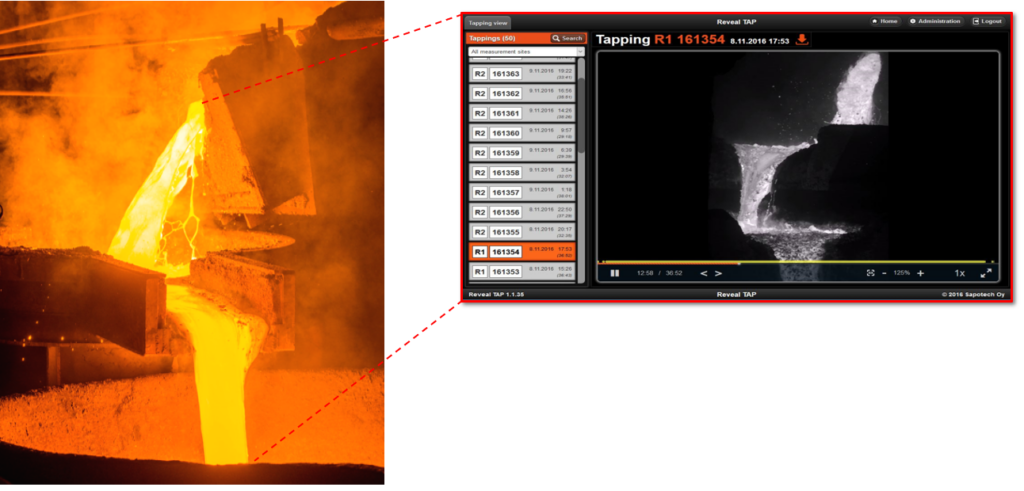

Based on the use of high-resolution infrared cameras and algorithms, Sapotech’s Reveal TAP system detects the transition between metal and slag during the tapping process and alerts the operators. The system can be used in processes like Argon Oxygen Decarburization (AOD), Electric Arc Furnace (EAF), Basic Oxygen Furnace (BOF), and copper converting. Reveal TAP for metal/slag detection has also been successfully implemented for different metals in many different locations. Figure 2 shows an example from ferrochrome furnace tapping.

A couple of case examples where Sapotech’s Reveal TAP system for metal/slag detection has been applied:

- EAF process: In EAF tapping, slag ending up in the ladle is an undesired result and increases the needed operations in the secondary steelmaking. With the use of Reveal TAP system, it is possible to detect the transition from steel to slag in real time resulting lower slag carry-over and decreased secondary refinements.

- Copper converter: Another case involved the use of Reveal TAP system at a copper converter. The customer’s primary goal was to minimize the loss of copper during the tapping phase. The system enables early detection of copper in the slag stream, which allows the customer to take immediate actions and prevent the loss of copper.

Figure 2. A reference picture of Reveal TAP used during tapping.

The setup for stand-alone system is straightforward and simple, comprising just a few key components (Figure 3). It includes one high-resolution infrared camera, positioned to monitor the tapping stream. The Reveal software is installed on a camera controller for data processing, which is also used to store short-term data. Additionally, the system can also be integrated with the customer’s automation system. This integration not only improves the process traceability but also boosts the overall efficiency and the produced data and signals can be further used to improve the automation of the tapping procedure.

Figure 3. An example of system setup: imaging units (1) and control cabinet (2).

For post-process analysis and review, the system includes Sapotech’s user-friendly interface, where users can access the videos and other process data from the tapping process later. This supports further process development and is the ideal tool for analyzing process deviations, even weeks or months after the actual tapping event.

In the next chapter, some of the benefits of the Reveal TAP system are presented.

Benefits

Sapotech’s Reveal TAP for metal/slag detection system offers the following benefits to its users:

- Metal/Slag free tapping: The system detects metal/slag in the tapping stream, alerting the operators.

- Higher yields: Efficient detection ensures that only the desired metal is processed further, leading to improved yield in the metal production process.

- Better product quality: Slag/metal detection ensures that the product meets the required quality standards.

- Reduced treatment costs: By optimizing the process, treatment costs can be reduced as the system helps to avoid excessive use of deoxidizers and reduces phosphorous pick-up.

- Systematic documentation: Tapping process tracking and documentation enable data-driven decision-making.

- Analysis of process deviations: System can help to identify potential process deviations, allowing users to address them immediately.

- Improved worker safety: Better control of the process and real-time alerts help to minimize the risks of potential accidents.

- Easy information sharing: Data is stored to the Reveal Platform with easy access and user-friendly interface.

- Economic savings potential: There are several economic benefits, including avoided consumptions of deoxidizers in ladle treatment, reduced phosphorus pick-up, and decreased refractory wear, resulting in costs savings.

In summary, Reveal TAP for metal/slag detection is a great addition to metal production processes. Automatic alarms and real-time process monitoring make it easier for the user to operate the process. The system is also quick and easy to install. The hardware is designed to withstand extreme temperatures and challenging process conditions. However, as industry standards evolve, Sapotech’s commitment to continuous improvement ensures that the Reveal TAP system will continue to evolve as well, providing metal production industries with advanced solutions for years to come.

If you have any questions about the article or Reveal TAP system, don’t hesitate to contact us.

The next Reveal TAP article will focus on well filler monitoring. Stay tuned for our latest articles and news by following our LinkedIn page!