Sapotech’s article series continues by delving into the various applications of Reveal TAP. This article discusses the use of Reveal TAP for tuyere area monitoring, providing more detailed information about the system’s capabilities and benefits.

Description

Stainless steel production uses converter processes as a crucial step for refining the composition of the molten metal. Specifically, these processes play a key role in ensuring the desired quality and characteristics of stainless steel achieved. Two types of converters are used in this refinement process, the ferrochrome converter (CRK) and the argon oxygen decarburization (AOD) converter. In the case of ferrochrome converter, its primary purpose is to enhance the quality of ferrochrome by eliminating impurities and adjusting the alloy’s composition. This is achieved by removing silicon and part of the carbon from the molten ferrochrome by blowing oxygen into the melt. Subsequently, the AOD converter takes the refinement process to the next level by further reducing the carbon content in the melt and oxidized alloying elements are reduced back to the steel bath.

However, these refinement processes cause significant thermal, mechanical, and chemical stress to the converters. The refractories, which are the heat-resistant linings that protect the converter’s interiors, and the tuyeres, which are nozzles through which oxygen and other gases are injected, experience constant wear and tear. This causes gradual accumulation of material and erosion to these parts of the converter, which can lead to negative impact on the overall process performance and in the worst case, steel break-out.

Traditionally, operators asses the tuyere area conditions from the sampling hole, but this approach has several limitations. It can be time-consuming, imprecise, and includes many safety risks. Sapotech’s innovative solution, known as Reveal TAP for tuyere area monitoring, has been designed to address these challenges and improve the efficiency and safety of converter processes.

In the following chapters, we discuss the application of the Reveal TAP system and how it can be used in the converter processes providing significant benefits.

Application

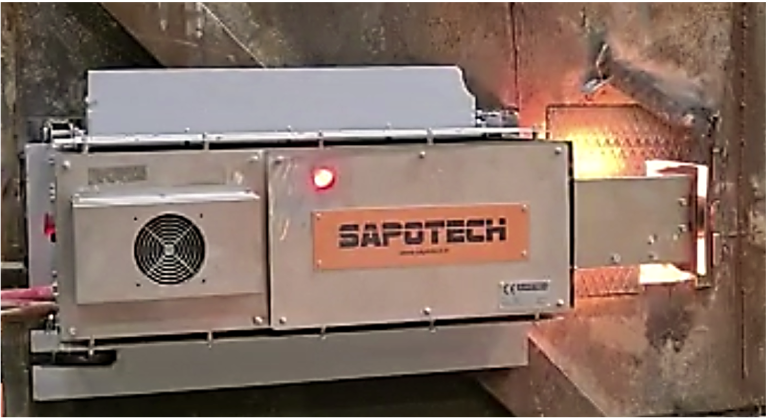

To systematize the tuyere area condition monitoring, Sapotech has developed a system that captures images of the tuyere area nozzles and surrounding refractories. This imaging process occurs once the converter has been tilted to the sampling position, ensuring a full assessment of the tuyere area. Figure 1 shows an example of the imaging process and the device itself.

Figure 1. Reveal TAP for tuyere area monitoring in imaging position.

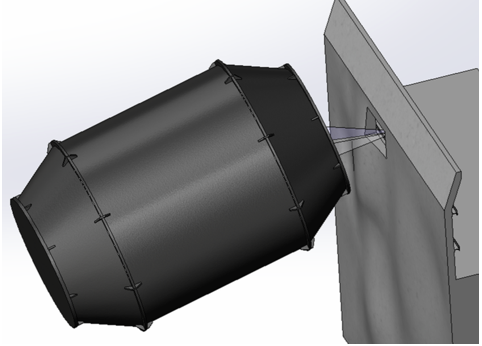

The system consists of a protective enclosure that contains all the key components of the system, such as an industrial camera mounted into a linear actuator. The camera is designed to move from the protective enclosure to the sampling hole, allowing it to capture images of the tuyere are and refractories (Figure 2).

Figure 2. An illustrated picture of the imaging process when converter is in the sampling position.

The entire imaging sequence is completed in approximately 20 seconds. The captured images are analyzed combining Deep Neural Network-based model with traditional image processing algorithms to extract information about:

- Position of nozzle tips and nozzle bases: By analyzing the captured images, the system determines the position of both the nozzle tips and their bases. This information offers an insight of the conditions of these components and possible material build-up inside the converter.

- Refractory wear around the tuyeres: The wear of the refractories can also be assessed from the captured images, which is important for understanding the state of these heat-resistant linings and identifying areas that may require maintenance.

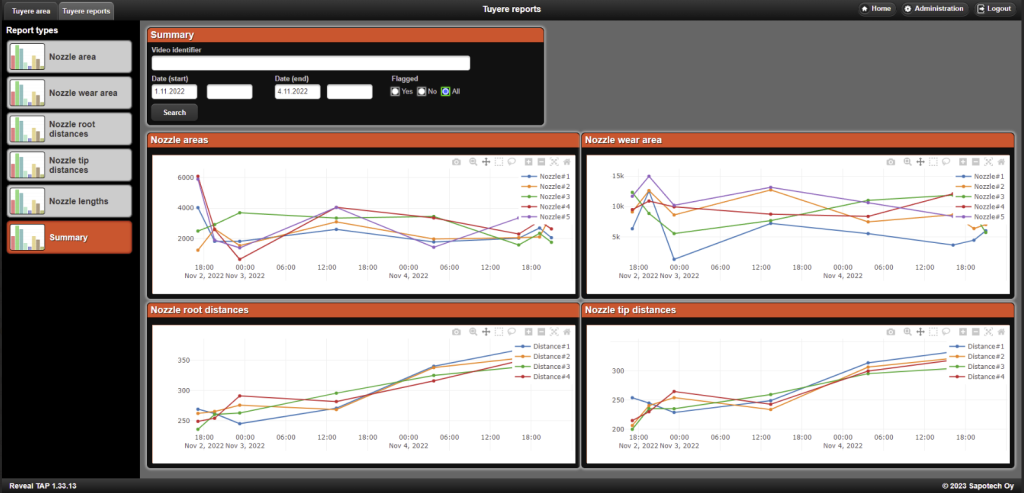

Videos and measurement results are displayed in Sapotech user interface for operators to check the condition of the tuyere area. In addition to tuyere area condition monitoring, the system also provides a feature for generating reports. These reports can be accessed from the “Reports” section and are a valuable resource for evaluating long-term trends and making conclusions about the remaining lifetime of refractories. In the picture below, an example is shown how these reports can look like (Figure 3).

Figure 3. Reports -section in Reveal TAP user interface.

In the simplest form, the system operates as a plug-and-play solution. Only power and compressed air is needed from the customer’s side. All the configuration work is done via Sapotech provided 4G/5G VPN device, there is no need for customer’s IT department to configure secure connections.

The activation of the imaging sequence depends on the case. In the absence of external trigger, the operator activates the imaging sequence from Sapotech user interface. On the other hand, when integration with automation system is done, the imaging sequence can be seamlessly automated. This system facilitates the exchange of information between Sapotech’s Reveal TAP system and the customer’s automation infrastructure, further improving the operational efficiency and data flow.

Benefits

Sapotech’s Reveal TAP – Tuyere monitoring system offers valuable benefits to its users, enhancing the efficiency and safety of converter processes in the stainless steel and in other metals industries:

- Immediate process evaluation: Changes in the tuyere area can be evaluated after every heat, allowing users to instantly see the impact of process changes.

- Data collection and storage: Data from the tuyere area is easily and safely collected and stored for later analysis.

- Consistent and objective decision making: Image data is always comparable; decisions can be made based on objective and consistent data.

- Preventing critical refractory damage: Captured images can reveal sudden catastrophic wear of refractories or the loss of individual bricks, helping to prevent breakouts.

- Trend indicators from algorithm detections: These include comparison of refractory wear and tuyere build-up to process practices, setting alarm limits, and even predicting converter tuyere area refractory life.

- Plug-and-play solution: The system is fast and easy to implement, minimizing disturbances to daily operations.

The converter tuyere area monitoring system is versatile and can be implemented not only to stainless steel, but also to other metals converting processes, where tuyere area is visible at some point of the processing. The hardware configuration of the system is designed to consider the space limitations, converter layout, and daily operations in the area. This adaptability ensures the system’s easy integration into different industrial settings, resulting in increased efficiency, safety, and data-driven decision making for its users.

If you would like more information about our Reveal TAP system, please do not hesitate to contact us.

The next Reveal TAP article focuses on how the system can be used for metal/slag detection. Stay updated on our latest articles and news by following our LinkedIn page!