Consistent and high slab quality is one of the cornerstones for high-quality final products as well as for efficient production and for short lead times. It is known that some of the events that may cause surface defects can be seen from the process data, such as solid mold powder tear-off. However, there are several defects that cannot be forecasted from process data. These are the most harmful defects born in the caster, because slabs cannot be automatically directed to grinding. One of our key customers wanted to improve further their slab quality by modifying caster parameters. Reveal CAST, which they had already installed in one of their casting lines was used in this development work.

Our solution

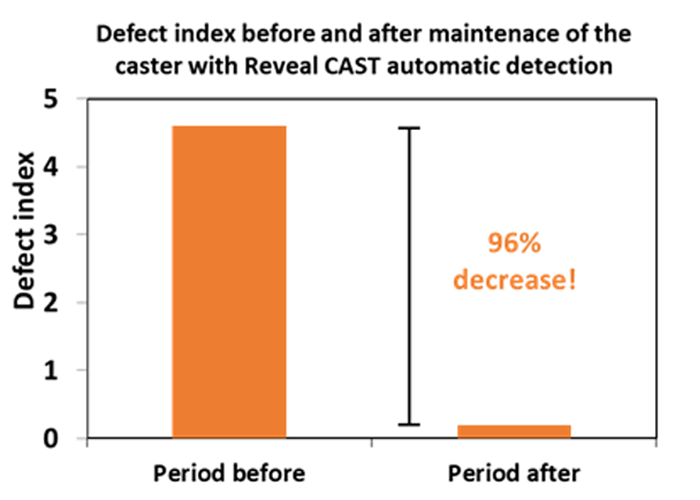

Reveal CAST with automatic defect detection algorithms was used to monitor the hot slab surface before and after the caster modifications. Our specialist developed specific indicators to follow changes on the surface quality of slabs. There are several indicators for different type of defects, which were integrated as a one single defect index.

Benefits for the customer

Reveal CAST proved that it not only monitors the surface condition of slab surface with high reliability, but also contributes to improved production efficiency at the steel plant. With Reveal CAST our customer could follow the effect of the modifications in caster in real time and verify that the changes were successful. Reveal CAST with automatic defect detection and defect indexing verified that the number of defective slabs was significantly reduced, from 1.5% to about 0.1%. Additionally, if quality problems appear again, it is very easy for maintenance personnel to react and make the necessary corrective actions, ensuring that consistent quality is maintained.